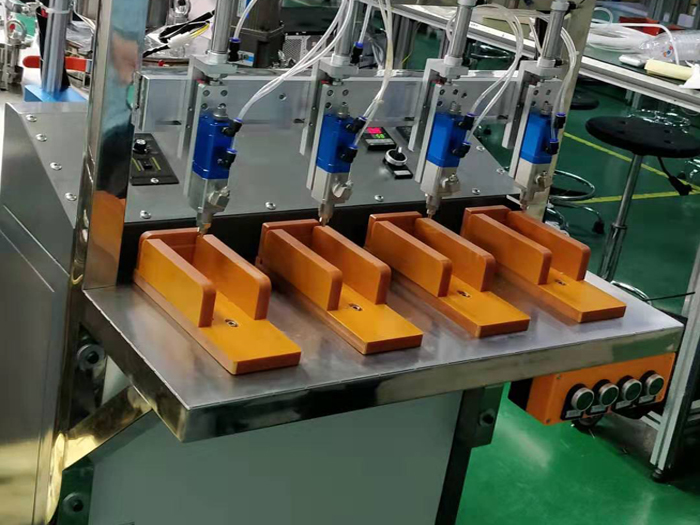

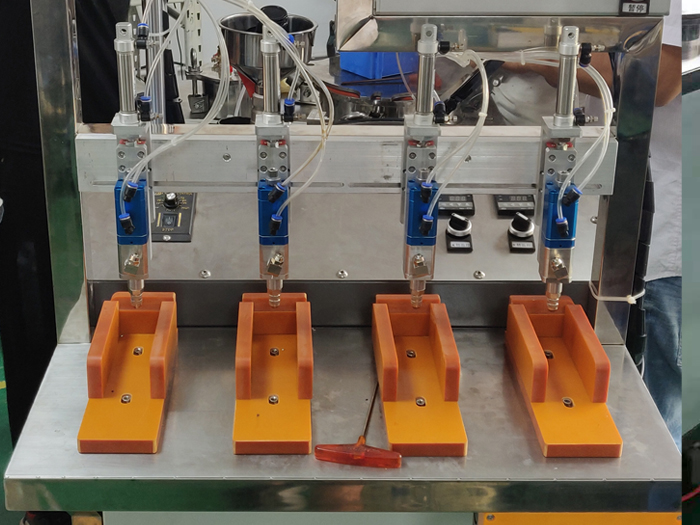

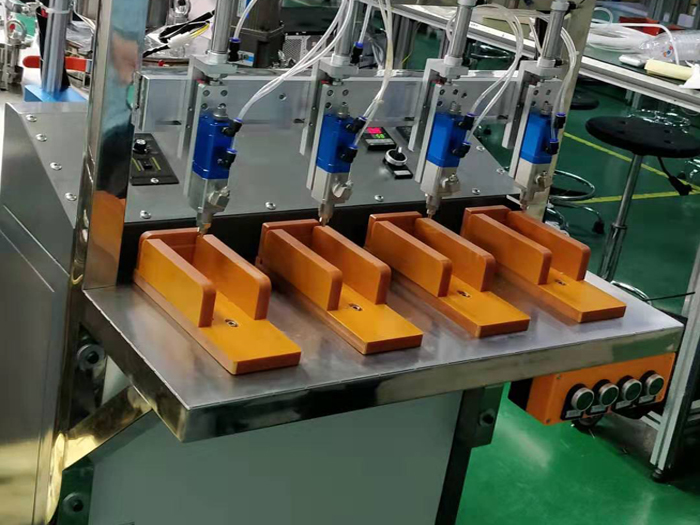

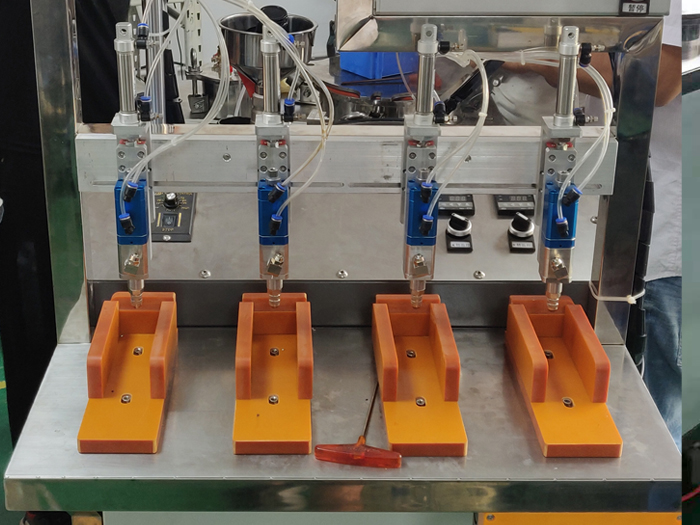

What are the functions of automatic glue filling machine?

作者:马交易 日期:2019-11-09 15:42 浏览:

The process of glue filling is used in the production of many electronic components, so what would you like to glue filling? What is the function of filling glue? Glue pouring as the name implies is to pour glue into an object. Do you know the function of glue pouring?

Glue pouring is a kind of dispensing, glue pouring, packaging, etc. which needs a large amount of glue. In the LED light, circuit board, waterproof LED light industry, it is easy to see the figure of glue pouring. Glue pouring is to spot a small amount of glue somewhere and then bond, such as electronic components, which need to use glue pouring.

Generally, there are two ways of glue filling, one is vacuum glue filling, the other is non vacuum glue filling. The glue filling function of the two ways is the same. Non vacuum glue pouring is to evenly pour glue into the interior or exterior of the product you need for glue pouring. It's also well understood if you use vacuum glue pouring, that is to say, glue pouring is carried out in a vacuum environment. This kind of glue pouring method is mostly used when there is no air or other trace elements in the interior. In this case, glue pouring can ensure that you won't say when glue pouring There is air entering the product, and it seems that a small gap will also be filled.

The function of glue filling is to reduce the service life of the products that need glue filling, such as the internal LED lamp, without external factors, and to extend the service life of the products. It also makes the products after glue filling easier to assemble with other parts. For example, the waterproof LED light needs to be filled with glue. After it is filled with glue, it can be waterproof and moisture-proof because its internal circuit is completely separated from the outside. In most cases, it operates normally and cannot be used due to external reasons.

Glue pouring is a kind of dispensing, glue pouring, packaging, etc. which needs a large amount of glue. In the LED light, circuit board, waterproof LED light industry, it is easy to see the figure of glue pouring. Glue pouring is to spot a small amount of glue somewhere and then bond, such as electronic components, which need to use glue pouring.

Glue pouring is a kind of dispensing, glue pouring, packaging, etc. which needs a large amount of glue. In the LED light, circuit board, waterproof LED light industry, it is easy to see the figure of glue pouring. Glue pouring is to spot a small amount of glue somewhere and then bond, such as electronic components, which need to use glue pouring.