High accuracy of COB dispensing controlled by visual dispens

作者:吴交易 日期:2019-08-07 19:33 浏览:

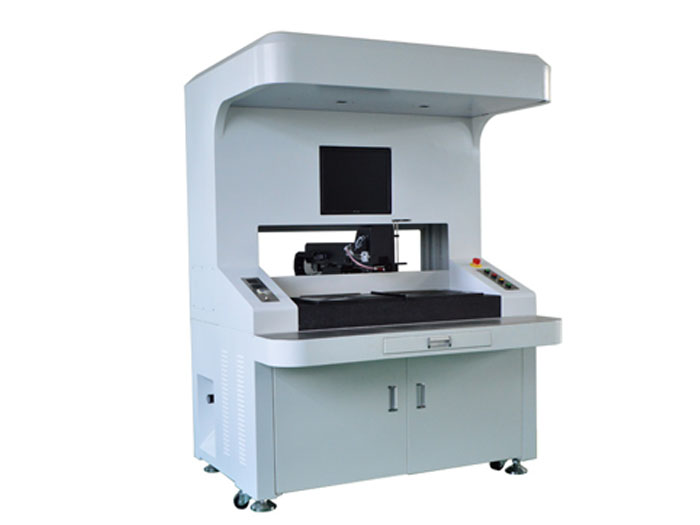

Visual dispensing machine is mainly used for dispensing COB electronic products. It adopts the static form of servo motor + ball screw, adopts computer control with charge coupled device assistant type compilation and teaching performance to enable coordinate trajectory position to be tracked and displayed in time, and can complete rapid programming. It can be divided into single-liquid dispensing machine and double-liquid dispensing machine. Many tasks can be accomplished by choosing multi-head fine-tuning bucket fixture.

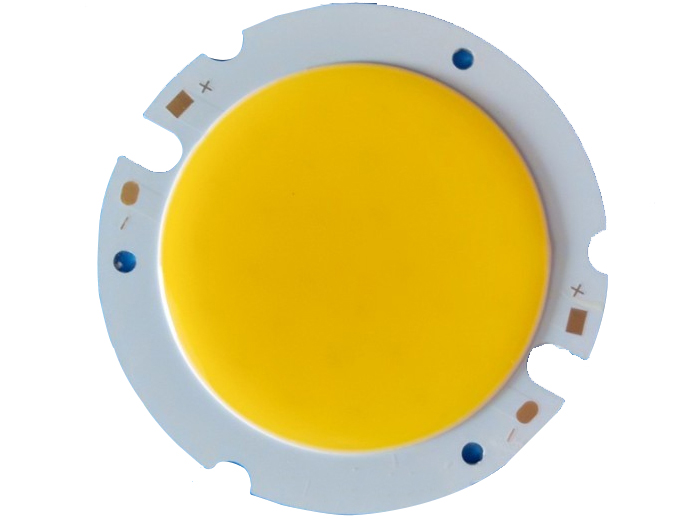

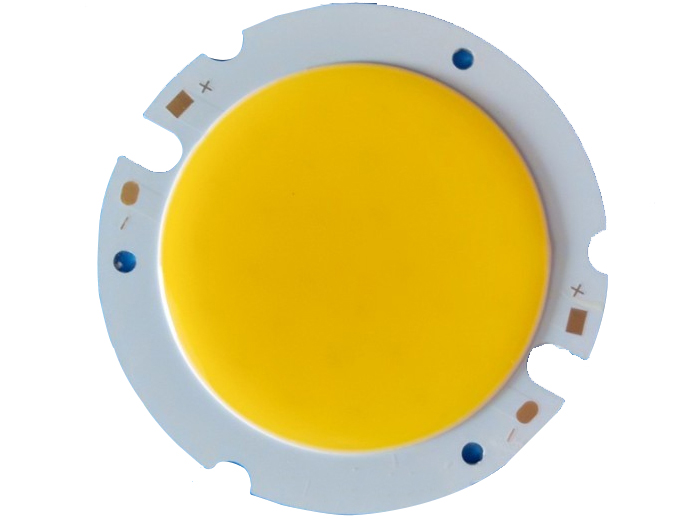

COB dispensing is one of the chip packaging technologies, which installs semiconductor chips on printed circuit boards by replacing them. The electrical connection between the chips and the boards is sutured by leads. After the completion of this method, COB black glue (COB adhesive) is coated to ensure reliability.

Applications: Mobile phone motherboard, computer motherboard, printed circuit board, liquid crystal display, DVD, calculator, instrument, semiconductor and other electronic products.

1. Visual dispensing machine uses panoramic camera to actively identify debris and intelligent detection. When dispensing positioning, it does not need to use common tools for positioning. It can also use indirect sealant of aluminium sheet boxes to complete COB dispensing.

2. Sealants in circular area can be indirectly packaged at a single point, with sealants at 3000 points per hour.

3. Actively optimize dispensing routes and effectively limit the production capacity of promotional products;

4. The shape of COB dispensing can accomplish the continuous and triaxial linkage of points, lines, surfaces, arcs, circles or irregular curves.

5. The glue quantity, thickness, speed, time and stop time can be set. The glue is stable and does not drip.

6. Vision can complete the preheating performance of COB substrate in advance and save the time of fetching and placing.

7. Visual dispenser actively detects and installs glue volume of equipment, and actively sends out sound and light alarm before glue shortage.

8. Guns and hoses have heating properties, which enhance the fluidity of glue and ensure the stability and consistency of sealing shape.

9. The active recognition performance of the substrate height can be selected. When the substrate is deformed, the glue head can adjust the dispensing height by vision.

4. The shape of COB dispensing can accomplish the continuous and triaxial linkage of points, lines, surfaces, arcs, circles or irregular curves.

4. The shape of COB dispensing can accomplish the continuous and triaxial linkage of points, lines, surfaces, arcs, circles or irregular curves.