Inductor coil glue filling

作者:马交易 日期:2019-12-24 19:12 浏览:

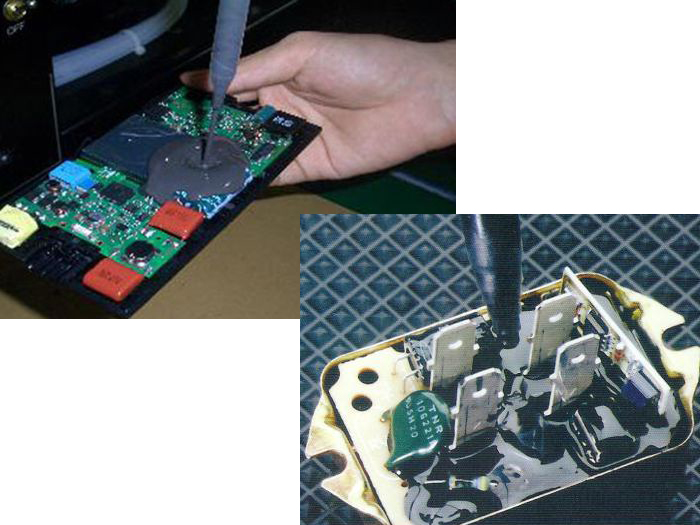

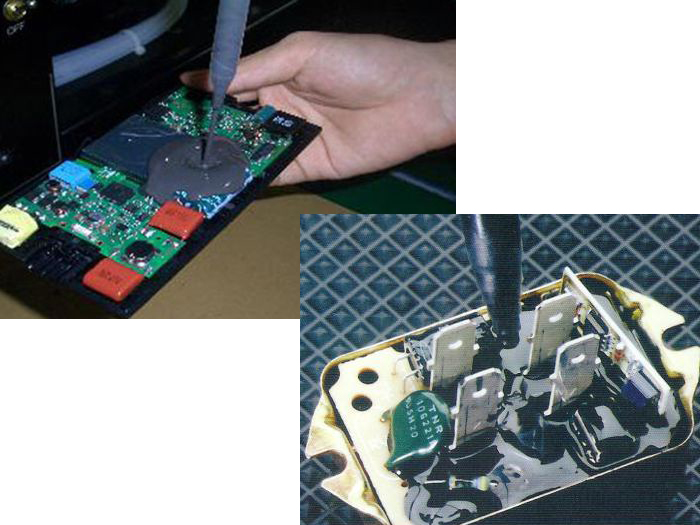

Inductor coil glue filling is used for peripheral glue filling, fixing coil and black frame, preventing coil disorder and influence on magnetic field. Product glue filling requires a large amount of glue, which is used in a large amount every day. Epoxy resin glue is used for glue. It is cheap and easy to glue. After glue solidification, it has heat dissipation and sealing effect. It is a better glue than single component glue Use.

There are two types of machines that can fill the inductor coil. According to the manufacturer's production capacity, if the manufacturer produces 20000 inductor coils every day, it will use the floor type automatic glue filling machine, which can produce 3000 to 5000 per day. It can use the double Y-axis automatic glue dispenser, and the glue ratio is 2:1 and 1:1. The floor type automatic glue filling machine can work at 10:1, 5:1 and 1:1, because the floor type automatic glue filling machine has high performance, More in line with the requirements of inductor coil glue filling, the manufacturer recommends the use of floor type glue filling machine.

There are also manufacturers that use single component glue for glue pouring, which is not conducive to production. The properties of single component are not appropriate. Although it is capable after glue pouring, the life effect is not as good as that of epoxy resin glue, which has been tested many times and actually produced by the manufacturer. The effect of two-component glue pouring is better than that of single component glue, of course, not all glues are the same. It needs to be based on The cost of glue determines that silica gel is used for energy-saving lamp dispensing, and the cost is different, but the filling of inductor coil is mainly composed of two components.

Single component glue is used for energy saving lamp dispensing, because the machine cost is low and the glue price is low, so it does not need too much cost, and it can also be finished by using double Y-axis automatic dispensing machine, so the application effect is very good. As long as it can meet the production requirements, it can be done. It's that type of machine and glue, and it's not important to choose the right one. This is the case for energy saving lamp dispensing and inductive coil filling machines