The transmission is poor after the drive is filled with glue

作者:点胶机 日期:2020-07-25 22:21 浏览:

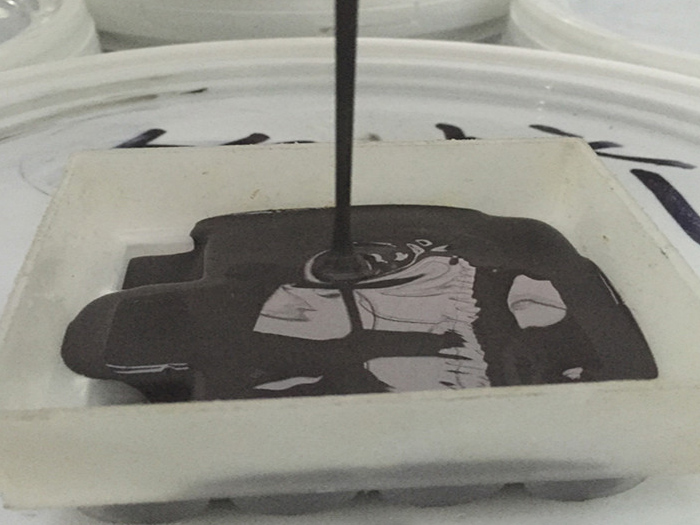

The main reason for poor transmission after driving glue pouring is that the glue has a certain blocking effect, just like the wall, it will have the effect of signal isolation. If the product is to be sealed by glue, it needs to use a sensor with better effect, so as to avoid that the sensing effect can not be exerted, which will lead to poor product quality, which will affect the product quality and directly lead to drive scrapping.

In fact, the thickness of driving glue is not very thick, about 1cm. If these sensors can not work well, it proves that the quality is very poor. If you want to drive well, the sensor effect must be good. Choosing brand sensor can guarantee the quality! Some of them are directly installed on the driver because they haven't been tested. They need to be tested before use. The manufacturers of electronic products can't guarantee that every one is good!

The sensor is usually used for waterproof glue filling of power supply. The whole surface is sealed inside to avoid the influence of internal parts. However, no manufacturer has ever responded. After gluing, the sensing effect becomes worse, which must be directly related to the sensor device used. Although the glue has the isolation effect, it will not be so. There are tests on the waterproof grouting of power supply, but the characteristics of the glue are really not done The law is completely cut off, which cannot be changed.

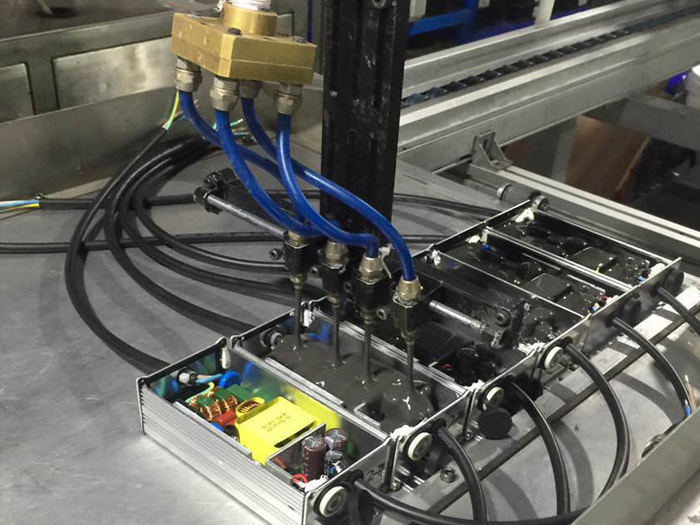

Our company is a manufacturer of floor type gluing machine, which is often used in power supply waterproof gluing. We also know some of them. When driving the glue, the sensor will become poor. It is recommended to replace the sensor manufacturer and replace the sensor. If you need the floor type glue pouring machine, you can choose our company. We specialize in manufacturing glue pouring machine, with a wide range of applications and special stainless steel points It has strong mixing effect.

At present, the stainless steel dispensing valve can meet the glue within 3:1, which is indeed in line with the modern glue pouring demand. It can mix glue very well, and the mixing ratio can reach 98%. The effect is really excellent. Moreover, we are a manufacturer specializing in the production of floor type glue pouring machine. We can make glue filling scheme to make it meet the requirements of pouring core.