Single component silica gel filling machine suitable filling

作者:涂胶机 日期:2020-04-11 16:15 浏览:

There are differences between two-component and single-component silica gel filling. Single component does not need too complicated operation requirements. We recommend two types of filling machines that can meet the requirements of single-component silica gel filling. They are semi-automatic and full-automatic. The dispensing valve and machine we developed according to the characteristics of silica gel can use silica gel for filling very well.

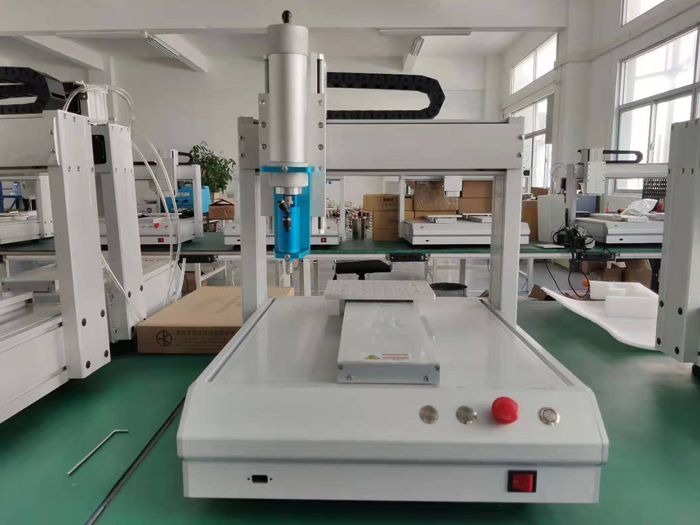

Automatic dispensing machine

The machine is equipped with stainless steel liquid level display pressure barrel + double hole dispensing controller and large flow silica gel dispensing valve. The special dispensing valve uses single component silica gel to inject glue. The rubber cylinder is very large, and the internal cylinder has unique structure, which can provide greater thrust to ensure that silica gel can be pushed out. There is a disc on the axis, which can strengthen the effect of glue pushing, thus solving the problem of single component silica gel pouring The machine can realize full-automatic production and complete the task of glue filling without pressure.

Semi automatic dispensing machine

Compared with the full-automatic system, the semi-automatic system is simpler. The viscosity of silica gel cannot be too high. The semi-automatic system can only be used if it has certain fluidity. The requirements are relatively high. Compared with the dispensing effect, our company also considers that there are two semi-automatic dispensing machines that meet the requirements. The first one is manual dispensing valve + pressure barrel, the second one is large flow dispensing valve + double porosity controller + liquid level display pressure Force bucket, do not need to move the platform, manually control the dispensing valve, and then dispensing, still can achieve dispensing.

The difficulty of silica gel dispensing lies in the viscosity and packaging of the glue. The viscosity of the glue is high. Generally speaking, the dispensing accessories are not suitable. If the package has bulk, support and silica gel capacity, the storage fixture should be manufactured according to the requirements, which is helpful for dispensing. The difficulty of single component silica gel dispensing is just these. At present, except for the ultra-high viscosity silica gel, other requirements are basically met.

The adult product glue filling machine is mainly used for glue viscosity and proportion. Generally, the control proportion is quite low. Our company can meet the use requirements. The product glue filling effect will also have a good effect. Our company has made corresponding cases! The filling effect of adult products can meet the strict standard. There is a special filling machine for adult products to meet the difficulty of silicone dispensing, and the use effect will be better.